Our services are guaranteed to be high-quality With a 3 to 6 Month Warranty on workmanship.

Our Fun Facts

Dream It, We Can Built It

We strive to consistently exceed customer expectations and create innovative solutions to fit any need. Keeping up with new trends and market demands while combining our technical and artistic expertise.

1k+

Satisfied Clients

1

Projects Completed

1

Metal Works

Our Services

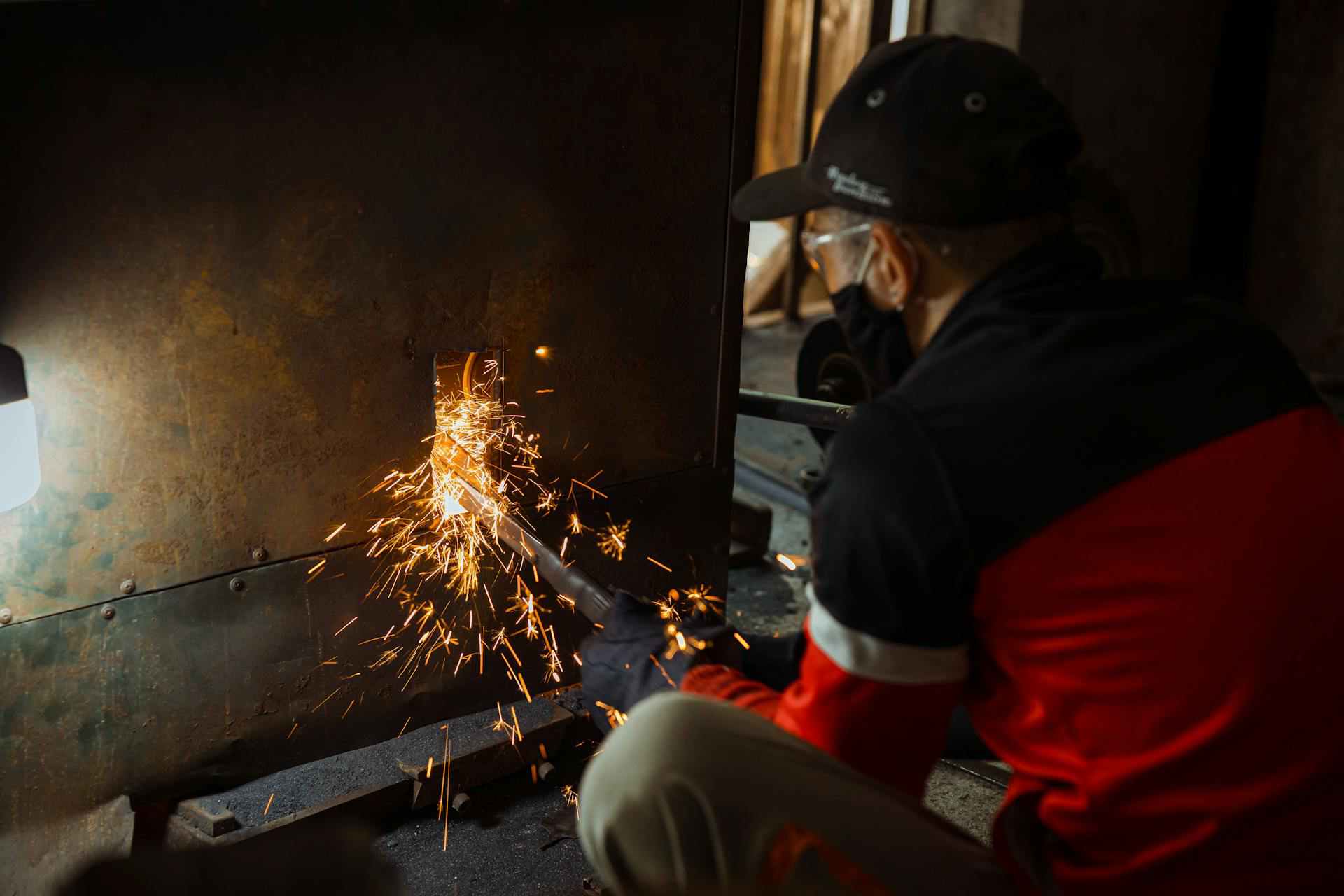

Elevate Your Business With Top Notch Welding

Why Choose Us

Why You Should Choose Our Welding Company?

By selecting Khetho Engineering, you are choosing a trusted partner that combines experience, innovation, and customer satisfaction to deliver superior welding and engineering services tailored to your specific requirements.

Welding

Metal Work

Steel Weld

Seamless Solutions Welded With Care

Our Services

What We Offer

Metal Works

Metal Works refers to the process of shaping, cutting, welding, and assembling metal materials to create a wide range of products and structures. This includes fabricating parts for industries such as construction, automotive, aerospace, and manufacturing. Metal works can involve techniques like welding, machining, casting, and bending to produce custom metal products, structural components, and industrial equipment. The process is critical for creating durable, functional, and high-performance metal structures or parts tailored to specific needs.

Read More ->

Steel Welding

Steel Welding is the process of joining steel components using heat and/or pressure to create strong, durable bonds. It is commonly used in construction, manufacturing, and repair projects, where precision and strength are critical. Various welding techniques, such as MIG, TIG, and Stick welding, are employed to ensure reliable welds that can withstand heavy loads and harsh conditions, making it an essential process in building steel structures, pipelines, and other industrial applications.

Read More ->