About Us

Why Choose Us.

At Khetho Engineering, we specialize in transforming steel into high-performance solutions that drive your projects forward. Our state-of-the-art facilities are equipped with the latest technology and machinery, enabling us to craft steel components with unparalleled accuracy and durability. Whether it's structural steel for towering skyscrapers, reinforced components for manufacturing, or specialized products for the energy sector, we have the expertise and resources to meet your unique requirements.

Our core services include:

- Steel Fabrication and Customization: We offer tailor-made steel products designed to your exact specifications, ensuring they are not only functional but also optimized for performance and cost-effectiveness.

- Advanced Engineering Solutions: Our skilled engineers employ advanced design techniques to provide innovative solutions, helping you overcome any engineering challenge with precision and efficiency.

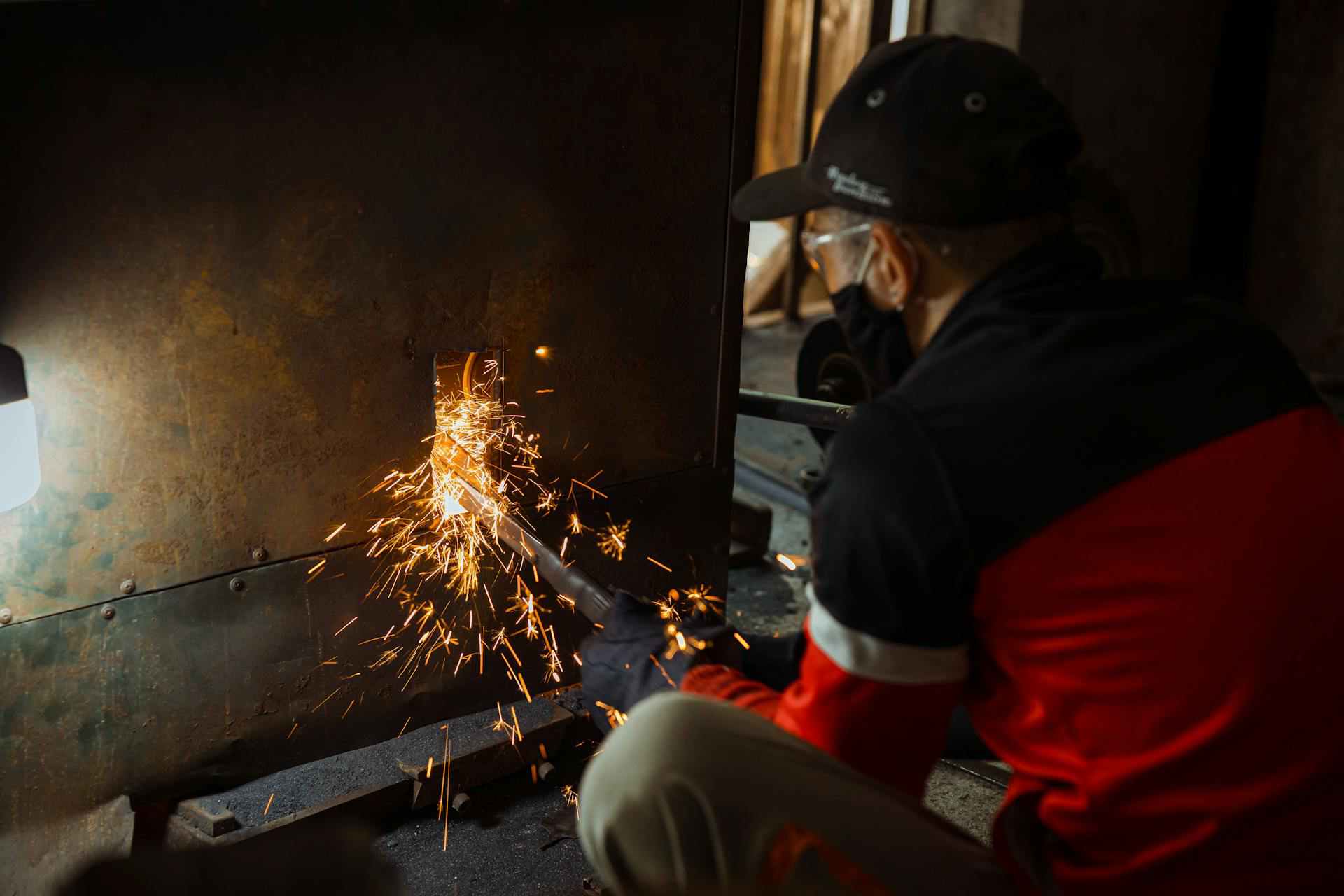

- Cutting-Edge Production: From the initial steel processing stages to the final product delivery, our production methods are designed to uphold the highest standards of quality and safety. We utilize advanced welding, cutting, and finishing technologies to bring your vision to life.

- Sustainability Focus: At Khetho Engineering, we recognize the importance of sustainability in modern steel production. Through eco-friendly practices and the use of recycled materials, we contribute to a greener, more sustainable future.

What sets us apart is our dedication to our clients. We work in close collaboration with you to ensure that every project is completed on time, within budget, and to the highest standard. Our team of skilled professionals is always ready to go above and beyond, providing expert consultation and support at every stage of the process.

At Khetho Engineering, steel is more than just a material—it's the foundation upon which we build success, one project at a time. Let us be your partner in turning vision into reality.

Our Services

What We Offer

Types of Welding We Specialize in.

Welding Techniques: There are several welding methods used for steel, each suited to specific types of projects and steel grades:

MIG Welding (Metal Inert Gas): This is one of the most common welding techniques for steel, using a continuous wire feed as an electrode and an inert gas (like argon or CO2) to protect the weld pool from contamination. It’s known for its speed and ease of use, making it ideal for both thin and thick steel materials.

TIG Welding (Tungsten Inert Gas): In TIG welding, a tungsten electrode creates an electric arc, and filler material is manually fed into the weld pool. This process provides high precision and control, making it ideal for welding thin steel, stainless steel, and high-quality joints.

Stick Welding (Shielded Metal Arc Welding - SMAW): Stick welding uses a consumable electrode coated in flux to create an arc that melts both the electrode and the steel. This method is versatile and can be used in outdoor or challenging conditions, often for heavy-duty construction and repair work.

Flux-Cored Arc Welding (FCAW): Similar to MIG welding, FCAW uses a continuous wire electrode but with a flux core, which eliminates the need for shielding gas. It’s effective for welding thicker steel and works well in outdoor environments.

Submerged Arc Welding (SAW): In this method, the arc is submerged under a layer of flux, preventing spatter and creating a smooth, high-quality weld. It is often used in heavy industrial applications like shipbuilding or large steel structures.

Steel Types for Welding: Steel is available in various grades and compositions, including carbon steel, stainless steel, alloy steel, and tool steel. Each type of steel has unique welding requirements based on its chemical composition, strength, and hardness. Welders must choose the appropriate filler material, welding technique, and heat settings to ensure strong and defect-free welds.

Preparation and Techniques: Proper surface preparation is essential for successful steel welding. This includes cleaning the steel of rust, oil, dirt, or other contaminants to ensure that the weld will bond effectively. Techniques such as beveling the edges of the steel to form a groove for a deeper weld or preheating thick steel components to prevent cracking are common practices.

Heat Control: Controlling the amount of heat applied during welding is critical to avoid issues like warping, distortion, or cracking. Factors like steel thickness, welding technique, and the application’s specific needs will dictate the heat input and speed.

Post-Welding Considerations: After welding, the steel structure often undergoes a cooling period to ensure it retains its strength and integrity. In some cases, additional processes such as post-weld heat treatment or stress-relief annealing may be required to improve the steel’s properties, particularly in high-strength or critical applications.

Applications of Steel Welding: Steel welding is used in a broad range of industries:

- Construction: Steel structures such as beams, columns, and frameworks are welded to create stable, durable buildings, bridges, and other infrastructure.

- Manufacturing: Steel welding is essential in the production of machinery, equipment, automotive frames, and large-scale industrial systems.

- Energy Sector: Welding is crucial for assembling pipelines, pressure vessels, and other equipment used in oil, gas, and power plants.

- Repair and Maintenance: Steel welding is often used to repair cracked or damaged steel parts in both industrial and commercial settings.